10 years of experience

Offshore construction services

Оffshore construction – vessels and structures.

Offshore vessels are specialized vessels that serve industries such as oil and gas (resource exploration, well drilling, platform installation, subsea infrastructure, pipelaying, oil and gas platform support), wind energy (installation and maintenance of wind turbines), dredging, cable laying and repair, and many other industries.

At the same time, offshore platforms have become a critical element in meeting the world’s demand for oil and gas. These structures have changed the industry by allowing companies to explore and extract resources from the ocean floor.

There are different types of offshore platforms, each designed to fulfil a specific function. For example, fixed platforms are used in shallow water and are anchored to the seabed, while floating platforms are suitable for deep water and are tethered to the ocean floor. Other types include elevating platforms, compliant towers and tensioned platforms.

Construction of components for offshore platforms:

The process of building and installing offshore platforms requires careful planning, design and execution. The platform is first designed to meet specific criteria including environmental conditions, water depth and drilling requirements. After construction onshore, it is transported to the offshore site for installation. The installation process includes placing the platform on the seabed, securing it and connecting it to the subsea wells.

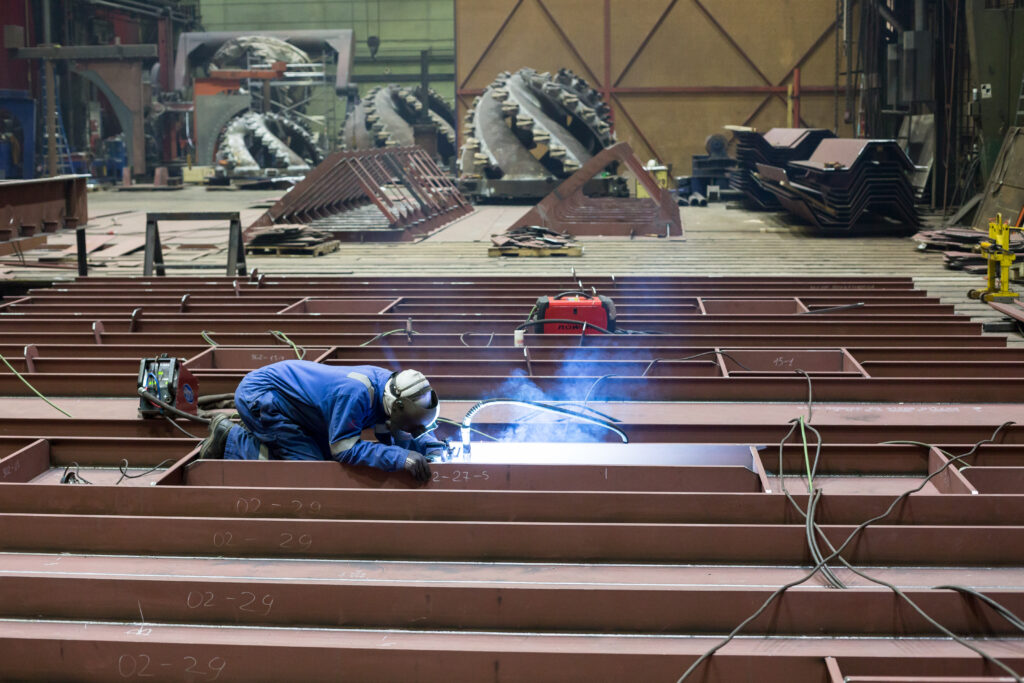

Navalis Group has more than a decade of experience in the construction of offshore vessels and structures. During this time we have participated in numerous projects at various shipyards. Since offshore platforms are built under harsh environmental conditions such as high waves, high winds and extreme temperatures, we ensure that all work meets high quality standards. The components we make for the platforms are durable and reliable, capable of supporting heavy equipment, machinery and personnel. We weld and assemble sections in dry docks and on site.

All offshore vessel construction work is carried out by qualified certified marine welders. All specialists have extensive experience and perform welding work on various types of offshore marine vessels for offshore operations. The main task of such a specialist is to ensure the strength and tightness of the structures on which the safety of the vessel or platform depends. The quality of work is crucial: welds must be able to withstand heavy loads, temperature fluctuations and seawater.

An important aspect of the work is compliance with quality standards and technical norms. Quality control includes mandatory testing of all welded joints, their strength and durability. To guarantee the quality of our work, we carry out regular DNT control procedures.

Our primary goal is to provide the best quality possible. Contact us to determine the details of your project today!

We are waiting for your messages!

Leave your details and we will contact you shortly

Your message has been sent!

We will contact you as soon as possible!

See Also

Navalis Group at Nor-Shipping Oslo 2025: New partnerships

Participation in the exhibition reaffirmed Navalis Group’s commitment to expanding its international partnerships, adopting modern practices, and contributing to the evolution of the global maritime sector.

Navalis Group at Seatrade Cruise Global: Expanding Horizons Through International Collaboration

Last week, Navalis Group proudly participated in Seatrade Cruise Global, one of the world’s most prominent events in the cruise and maritime industry, held in the United States.